Wondering how to measure airflow in a duct? You’re not alone! If you are a homeowner wanting to improve your HVAC system’s efficiency or just curious about air flow CFM, this guide is for you. Proper airflow—measured in cubic feet per minute (CFM)—keeps your home comfortable, cuts energy costs, and extends your system’s life. We’ll break down what CFM means, show you step-by-step methods to measure it with tools like an anemometer, and share tips to fix common issues.

What Does CFM Stand For?

CFM, or cubic feet per minute, measures how much air moves through your HVAC ducts every minute. It’s a key metric in HVAC systems because it shows if your rooms are getting enough air. Here’s why it matters:

- Comfort: Low airflow can make rooms stuffy or unevenly cooled.

- Efficiency: Poor airflow spikes energy bills by overworking your system.

- Durability: Blocked ducts strain your HVAC, leading to repairs.

Imagine your HVAC as a car engine—cubic feet per minute airflow is like the fuel mix keeping it running smoothly. Curious about what does CFM stand for or what is CFM in HVAC? It’s the amount of air your system delivers. Understanding this is the first step. CFM, or cubic feet per minute, shows how much air moves through your HVAC ducts each minute. It’s a key metric in HVAC systems because it shows if your rooms are getting enough air. Here’s why it matters:

- Comfort: Low airflow can make rooms stuffy or unevenly cooled.

- Efficiency: Poor airflow spikes energy bills by overworking your system.

- Durability: Blocked ducts strain your HVAC, leading to repairs.

Imagine your HVAC as a car engine—cubic feet per minute airflow is like the fuel mix keeping it running smoothly. Curious about what does CFM stand for or what is CFM in HVAC? It’s simply the volume of air your system delivers, and understanding it is step one.

Why Measuring Airflow Matters

Ever asked, “Why isn’t my HVAC cooling properly?” Chances are, it’s an airflow issue. Measuring air velocity and CFM measurement helps you spot problems like:

- Dirty filters clogging the system.

- Leaky ducts wasting air.

- Undersized ducts choking airflow.

Fixing these saves money and keeps your home cozy. For a deeper dive, check out ASHRAE’s airflow standards.

Tools for Measuring Airflow in a Duct

To measure CFM, you’ll need the right gear. Here’s what works:

- Anemometer: Measures air velocity in feet per minute (FPM). Pair it with duct size for CFM.

- Flow Hood: Directly reads standard CFM—great for pros but pricier.

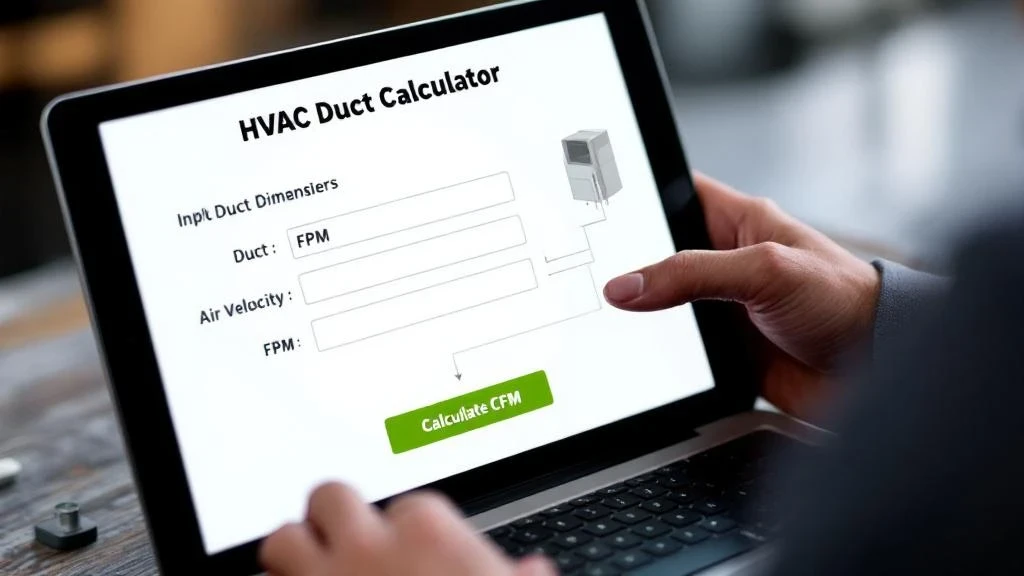

- Duct Velocity Calculator: Converts FPM to CFM online—perfect for quick math.

New to this? Start with an anemometer for HVAC. For pinpoint accuracy, ninjahvac.com technicians use flow hoods to nail CFM measurement.

How to Measure CFM in a Duct: Step-by-Step

Ready to learn how to measure CFM in your HVAC system? This simple step-by-step guide shows you how to use an anemometer to measure airflow. Airflow is measured in cubic feet per minute (CFM). Accurate CFM readings ensure your system runs efficiently, keeping your home comfortable and energy costs in check. Let’s dive in!

Step 1: Find a Straight Duct Section

Why It’s Key: Airflow can be inconsistent near bends, vents, or junctions, skewing your measurements.

How to Do It: Locate a straight section of ductwork at least 2 feet away from any bends, vents, or obstructions. This ensures stable airflow for an accurate reading.

Helpful Tip: The HVAC Duct Calculator from ServiceTitan emphasizes measuring in unobstructed areas for reliable results.

Step 2: Measure Duct Size

- For Round Ducts:

- Measure the diameter in inches using a tape measure.

- Calculate the cross-sectional area with this formula:

Area (in square feet)=π×( 2 diameter ) 2 ÷144 - Example: A 12-inch diameter duct has an area of π×(6)2÷144=0.785 \pi \times (6)^2 \div 144 = 0.785 π×(6)2÷144=0.785 square feet.

- Note: Dividing by 144 converts square inches to square feet, which is essential for CFM calculations.

- For Rectangular Ducts:

- Measure the width and height in inches.

- Calculate the area:

Area (in square feet)= 144 width×height/144 - Example: A duct 10 inches wide by 8 inches high has an area of (10×8)÷144=0.556 square feet.

- Why It Matters: The duct’s area is a critical factor in determining CFM.

Step 3: Check Air Velocity

- What You Need: An anemometer to measure air speed in feet per minute (FPM).

- How to Measure: Insert the anemometer into the duct and take 3–5 readings at different points (e.g., center and edges) to account for airflow variations.

- Calculate the average FPM from these readings.

- Example: Readings of 380, 410, and 390 FPM average to (380+410+390)÷3=393.33 (380 + 410 + 390) \div 3 = 393.33 (380+410+390)÷3=393.33 FPM.

Pro Tip: For best practices, refer to ASHRAE guidelines on airflow measurement.

Step 4: Calculate CFM

- Formula:

CFM = Average FPM x Area (in square feet) - Example: Using an average FPM of 393.33 and an area of 0.785 square feet:

CFM = 393.33 x 0.785 = 308.76 CFM (rounded to 309 CFM) - For Round Ducts: Simplify this step with the HVAC Duct Calculator, which converts FPM to CFM based on duct dimensions.

- Why It’s Reliable: This formula is the industry standard for accurate airflow volume.

Step 5: Analyze Results

- Compare to Ideal CFM: Check your HVAC system’s manual or manufacturer specs for the recommended CFM range.

- Example: A system might require 300–350 CFM—your 309 CFM falls within this range.

- Example: A system might require 300–350 CFM—your 309 CFM falls within this range.

- Troubleshooting:

- Too Low? Could signal clogged filters, duct leaks, or undersized ductwork. Too High? Might indicate an oversized system or improper balancing.

Quick Recap

- Measure Smart: Use a straight duct section and average multiple FPM readings for precision.

- Handy Tools: An anemometer is a must, and the ServiceTitan HVAC Duct Calculator streamlines calculations.

- Get Help if Needed: For expert advice or repairs, contact your local HVAC services.

With these steps, you’ll confidently measure CFM and keep your HVAC system performing at its best. Happy measuring!

CFM vs. FPM: What’s the Difference?

Confused about CFM vs FPM? Here’s the breakdown:

- CFM (Cubic Feet per Minute): Total air volume.

- FPM (Feet per Minute): Air speed.

To define CFM, multiply FPM by duct area. For example, 300 FPM in a 1-square-foot duct equals 300 CFM.

Troubleshooting HVAC Airflow Problems

Low air flow CFM? Here’s what might be wrong:

- Dirty Filters: Swap them every 1-3 months.

- Blocked Vents: Move furniture away.

- Leaky Ducts: Seal with tape or call ninjahvac.com.

- Small Ducts: A duct sizing guide can help— refer to the manufacturers installation manual for specific model requirements. Using a ‘ductulator’ can also help.

- Undersized Equipment: It’s possible the blower motor may not be sized correctly for the home. Refer to the manufacturers installation manual for the specific blower capacities.

Real-life fix: A homeowner found their CFM was half the norm due to a clogged filter. A quick swap, and comfort returned.

Tips to Improve HVAC Airflow

Boost your system with these HVAC maintenance tips:

- Duct Cleaning Benefits: Clear debris for better flow.

- Energy-Efficient HVAC: Upgrade ductwork and equipment for optimal cubic feet per minute.

- Airflow Measurement Tools: Use an anemometer regularly.

When to Call a Pro

Struggling with measuring air velocity in ducts? Complex systems or persistent ductwork airflow issues need expert eyes. Consider finding a trusted local service expert near you.

Conclusion

Knowing how to measure airflow in a duct is easier than you think. With tools like an anemometer and our guide, you can master CFM, tackle airflow in ducts explained, and keep your HVAC humming. For top-notch comfort and efficiency, ducts and equipment capacities must be correctly sized together.

0 Comments